Power Industry

Backed by proven engineering excellence and innovation, KAKATI liquid ring vacuum pumps and Condenser Air evacuation Packages are designed to deliver efficient, reliable, and cost-effective solutions for the Power Industry. Our strong presence and reputation in the power industry have been earned through consistent performance, robust quality, and long-term customer satisfaction.

KAKATI’s World Class Ǫuality, Unmatched Expertise and Sustainable solutions – a combination that helps Power plants in Condenser Air Evacuation, Ash Handling and Gypsum De-watering Applications.

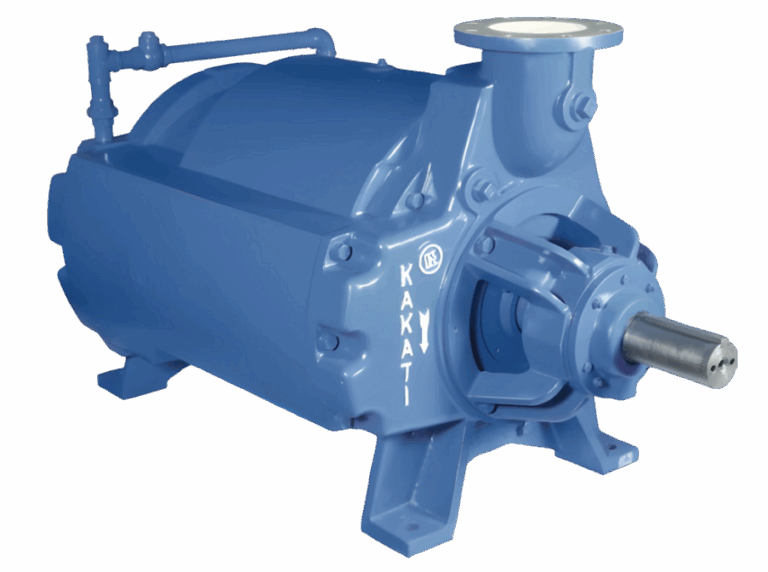

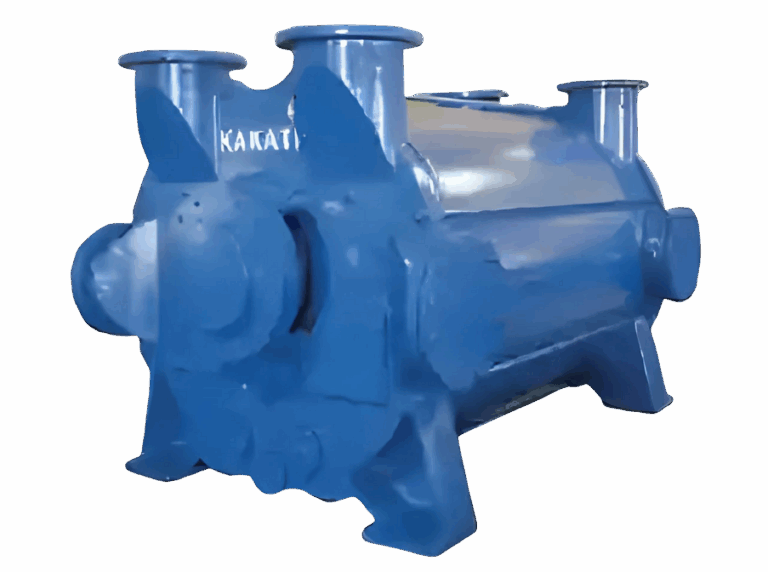

Kakati liquid ring vacuum pumps

are used in the Power industry for the following applications:

Condenser Exhauster Systems

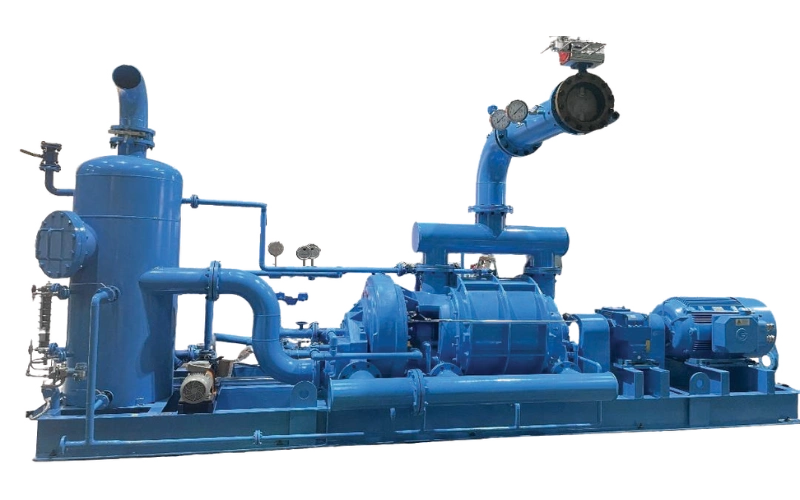

At the heart of every efficient power plant lies a dependable condenser exhauster system, and KAKATI’s solutions are designed to deliver exactly that.

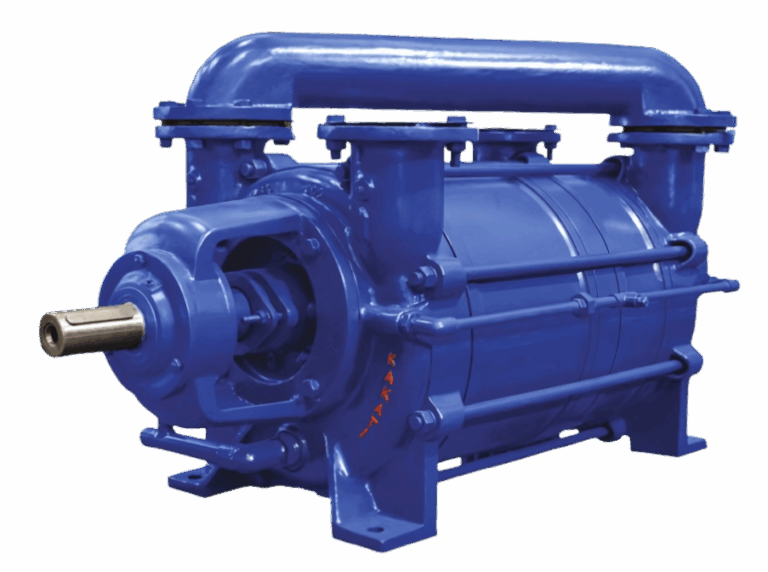

Our Condenser Air Evacuation Packages, suitable for power plants ranging from 20 MW to 800 MW, come as fully skid-mounted units complete with pumps, heat exchangers, separators, and control systems.

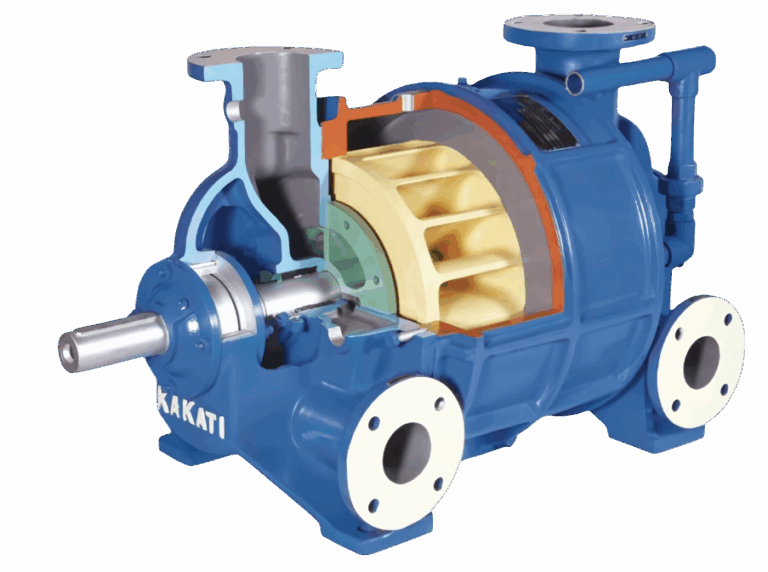

These are true industry workhorses built to last a lifetime. The conical pump design combined with shrouded rotors ensures high efficiency while eliminating cavitation, even under high vacuum levels.

KAKATI’s exhauster systems effectively remove air leakages and dissolved gases from condensers, lowering turbine backpressure. The result? Improved turbine output, better heat rates, and reduced operational costs all contributing to enhanced power plant performance.

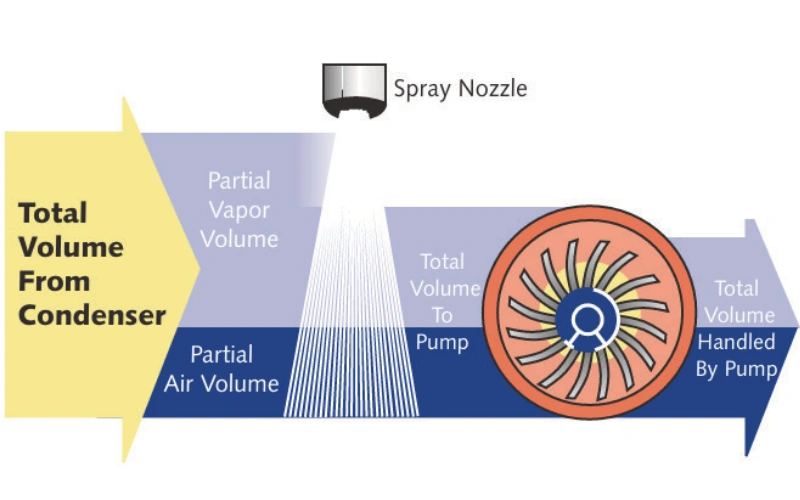

Capacity Advantage

Every detail in a KAKATI system is engineered for efficiency and our capacity advantage is a perfect example.

By condensing water vapour before it enters the liquid ring vacuum pump, the volumetric load on the pump is significantly reduced. This design approach directly translates into higher capacity and energy savings.

Behind this efficiency lies KAKATI’s optimised hydraulic design and precision-engineered porting, ensuring dependable performance during continuous power plant operations.

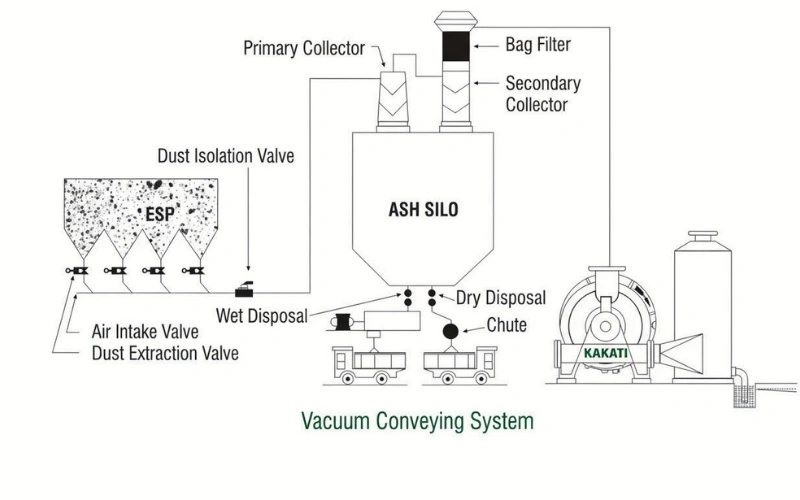

Fly Ash Handling :

This involves conveying fly ash from the precipitator hoppers to a central dry collectiom point under vacuum. A barrage of pumps work synchronously to evacuate the ash from the hoppers. A good vacuum system effectively reduces your carbon foot print.

- Over 3000 installations world wide

- Available in Cast iron, stainless steel and other materials of construction

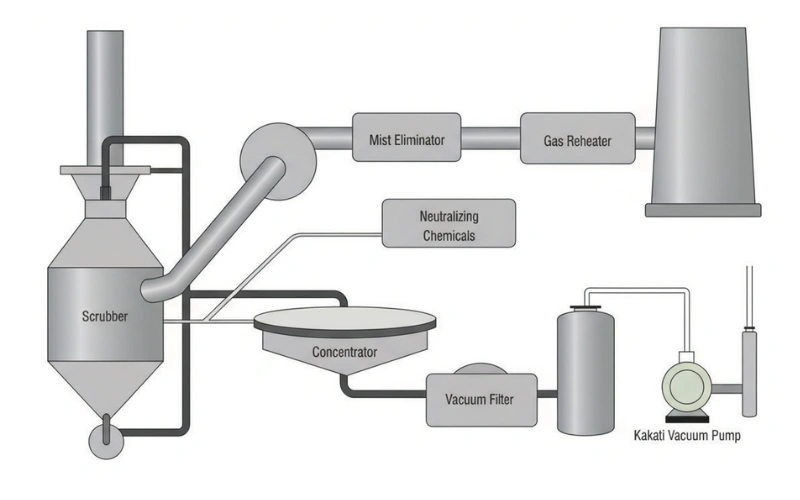

Flue Gas Desulfurization :

Kakati vacuum pumps are connected to vacuum filters effectively removing sulphur compounds from the aqueous slurry. A thoroughly designed pump can improve your process efficiencies and improve rate of separation.

- Over 500 installations in filtration applications worldwide

- Available in Cast iron, stainless steel and other materials of construction

Condenser Exhauster systems:

Kakati condenser systems are self-contained and effectively remove air leakages and extra dissolved air from condensers. This improves the turbine output by lowering turbine back pressure thereby improving heat rates and reducing production costs. The package comes Skid mounted with the pump, heat exchanger Separators and associated controls. These Exhausters are industry work horses and are built for a lifetime.

Kakati manufactures upto 40scfm capacity pumps according to HEI standards in both two stage pumps and air- ejector designs. Higher size exhausters can be designed upon request.

Two stage condenser evacuation system of conical liquid ring vacuum pump design

Hybrid Air-ejector and Liquid ring vacuum pump design

Spare pumps for two stage conical design vacuum pumps

Two stage condenser evacuation system of port-plate liquid ring vacuum pump design

Our Products for Power Industry

Have Questions or Need a Custom Solution?

Our experts are ready to help you find the perfect Kakati pumping solution tailored to your industrial needs. Get in touch with us today.